Equipment, materials, and technologies have become increasingly more sophisticated. As a result, stainless steel manufacturers can now provide a broader range of parts and components to an ever-growing list of industries. Today, multiple industries rely on sheet metal fabrication for precision-made finished products.

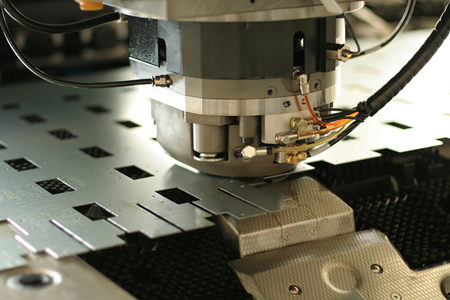

One of the key applications of sheet metal is in the field of fabrication. Sheet metal fabrication involves shaping, cutting, and bending sheet metal into various forms to create finished products. This process allows for the production of intricate designs and precise measurements, making it ideal for industries such as construction, aerospace, and electronics.

Sheet metal fabrication products can be found in everyday items like kitchen utensils, furniture, HVAC systems, and even architectural structures. The durability and strength of sheet metal make it a preferred choice for these applications as it can withstand heavy usage and provide long-lasting performance.

Moreover, sheet metal offers flexibility in terms of customization. Manufacturers can easily manipulate the shape, size, and thickness of the material to meet specific requirements. This adaptability makes sheet metal an excellent choice for creating unique designs or prototypes.

Light Fixture Industry

Take the light fixtures industry as a prime example. Using custom sheet metal fabrication, companies within this arena can have beautiful and functional light fixtures made. This includes lighting for commercial purposes, store fixtures, and a nice variety of display units. As for customization, this entails panels, punching, cutouts, metal forming, welding, and more.

In addition to high-quality materials, the best stainless-steel manufacturers offer different finishes. Of these, satin coat and galvanized steel rank among the most popular. Not only do these custom metal parts enhance the appearance of light fixtures, but they also serve as a layer of protection against moisture. Trusted sources offer spot welding and sub-assemblies as specialized services.

HVAC Industry

Then there is the heating, Ventilation, and Air-Conditioning (HVAC) industry. It too depends heavily on sheet metal fabrication for various parts. In addition to different raw materials, including aluminum and stainless steel, companies can choose from a variety of finishes.

Doing business with a top manufacturing company, customers have an added benefit of unique fastening techniques. The finished products keep HVAC systems running optimally. That means few operational issues and a long-lasting system. In fact, this ensures greater efficiency, which helps save money. As part of custom sheet metal fabrication, it’s important to work with a manufacturer that utilizes specialized tools that louver, lance, and emboss.

Additional Industries

Along with the two industries mentioned, many others require sheet metal fabrication for parts and components. Some examples of these include oil and gas, electronics, and medical. However, others on the list are construction, telecommunications, and automotive. When researching various stainless-steel manufacturers, it’s imperative to choose one with experience and expertise specific to the part or component needed.

After all, there are different categories for sheet metal fabrication.

- Commercial Fabrication – For this, a manufacturer produces goods specifically for consumer use. This includes electronics, light fixtures, appliances, and so on.

- Industrial Fabrication – As for industrial fabrication, the manufacturer makes parts used for other equipment and machinery. This covers tools like drill presses, bandsaws, and hydraulics, among others.

- Structural Fabrication – Sheet metal fabrication for this refers to metalworking that produces things for the building process. Typically, it includes large-scale products designed for buildings, shops, manufacturers, etc.

Serving Our Customers with Pride

When it comes to stainless steel manufacturers, Weldflow Metal Parts is a highly respected source in sheet metal fabrication industry. We understand that the customer base for sheet metal fabrication is on the rise. For that reason, we stay on track with trends and adopt cutting-edge technologies to continue providing our customers with superior service. Contact us today for more information or to discuss your project.