The medical sector is one of many that depends on quality fabricated parts and components. While some products make jobs easier, others help save patients’ lives. Although the best fabrication company uses different techniques based on what the customer needs, for this particular sector, steel laser cutting is one of the top choices.

Why is custom laser cutting so crucial for the medical sector? There are many reasons. Of all industries, the medical industry demands precision tools for minor and major procedures. Even one small defect could prove disastrous. For that reason alone, it works with top fabricators who use the laser cutting method when working with steel. You can better understand why this technique is so critical by considering some of its direct benefits.

• Smaller Medical Devices – Because sheet metal laser cutting makes fine and precise cuts, companies that manufacture medical devices can make them smaller than ever before. That makes it easier to move medical equipment around hospitals and clinics as needed.

• Cost-Savings – There is also a cost-savings factor to consider. Today, many medical facilities and professionals try to save money wherever they can, allowing them to pass those savings onto their patients. Laser cutting helps with that. Not only does it use very little power, but the cost of maintenance is minimal. Even if a laser-cutting machine breaks, the cost of replacement parts is nominal.

• Material Diversity – While many fabrication companies use custom laser cutting on metal, this process works on a broad range of additional materials, including glass, plastic, and even human tissue.

• Multiple Applications – As a safe process, laser cutting works extremely well for a host of applications.

In addition to making it possible for manufacturers to produce smaller medical devices, sheet metal laser cutting produces many other products used by experts in this field. As a prime example, this technique is ideal for cutting precision tubes such as vials for blood, urine specimens, and so on.

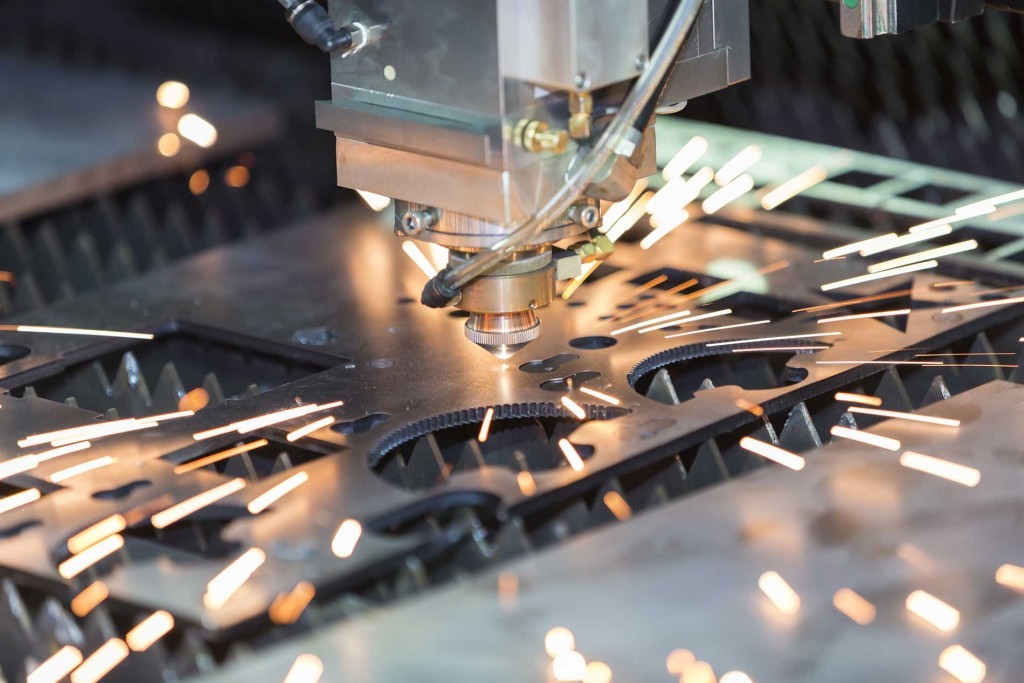

As a non-contact method of working with metal, the heat of the laser beam is what creates the product the customer needs. The result is a precise part or component. Because a skilled fabricator can control the heat output, intensity, and duration, he can use a variety of materials to make almost limitless cuts such as drilling, marking, engraving, and more.

Top Laser Cutting Fabrication Company

Weldflow Metal Products fabricates all types of finished products for multiple industries. We also service the medical sector with precision parts and components. As skilled professionals who use cutting-edge equipment, we stand behind every laser-cut product we make. For more information about this and the other services we provide, we invite you to visit our website or give us a call.