In 1967, Peter Houldcroft performed an experiment that involved cutting metal with a laser. From then on, laser cutting changed the industry of metal fabrication. Now, laser companies work with fabricators to bring more innovation into metal fabrications. With full automation in view, let us review how laser cutting companies are enhancing metal fabrication projects.

Manual Laser Cutting

Decades ago, a laser operator was always there to make manual adjustments to a laser cutting machine. Laser operators would make sure that the focal position, focal length, and cutting parameters were correct. They would also choose the right nozzle type and center it at the same time. As the machine operates, a laser operator would oversee the cutting. A tiny change in the nozzle’s position would alter the results. If the operator did not pinpoint and resolve this, the quality of the cut would not result in what the client wants.

It is clear that manual laser cutting caused delays in metal fabrication projects. In addition, programmed runs resulted in many erroneous cuts, leading to multiple revisions. Instead of devoting new sheets to the latest batch, the old set would get it for reruns.

Automation in Laser Cutting

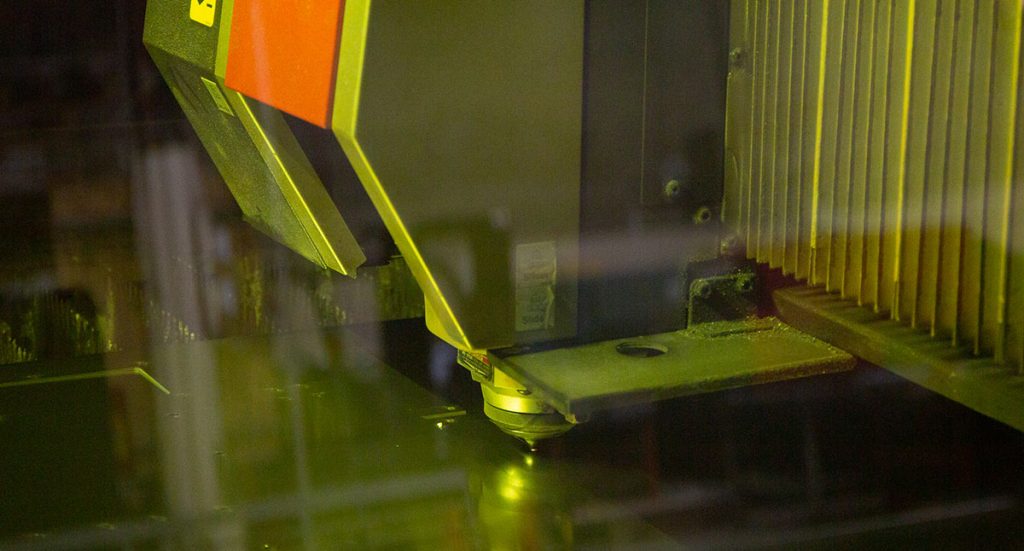

Technological advancements continue to pave the way for automation in various industries. Companies that specialize in metal laser cutting services are now working with fabricators to produce precision parts. They do so without the risks of manual laser cutting. The latest fixed cutting heads have different magnification levels that adjust the spot size and focal length. Its nozzle’s type and size can change based on the metal type. The machine can correct its own nozzle height and centering calibrations as well.

If ever the laser’s nozzle touches an adjacent section, the machine centers the nozzle. Companies engaged in providing custom laser cutting services have a monitoring system that inspects the kerf (cut channel) for any inconsistencies. In case of any irregularity, the system will go back to where the inconsistency happened and re-cut the part. It improves the cutting machine’s run during weekends and off-shifts even without human supervision. This saves time and money. It also prevents unnecessary errors and revisions.

Providers of Automated Metal Laser Cutting Services Help Produce Quality Metal Products

Automation in cutting operations improves the quality and increases the yield in metal fabrications. With automation, the cutting becomes quicker and more accurate. The fabricator does not waste time, money, and effort. Weldflow Metal Products works with experienced laser cutting companies. This gives you precision, flexibility, and efficiency. Contact us today if you want to know more about our custom laser cutting operations.