Innovative manufacturing technology has increased the demand for precise and efficient sheet metal cutting services. Current technologies are being implemented in the electronics, automotive, and construction industries to produce accurate parts. The most popular metal cutting methods—laser, plasma, and waterjet—are classified based on their distinct strengths and varied applications. Selecting the appropriate cutting method would significantly improve the cost and productivity factor in several projects.

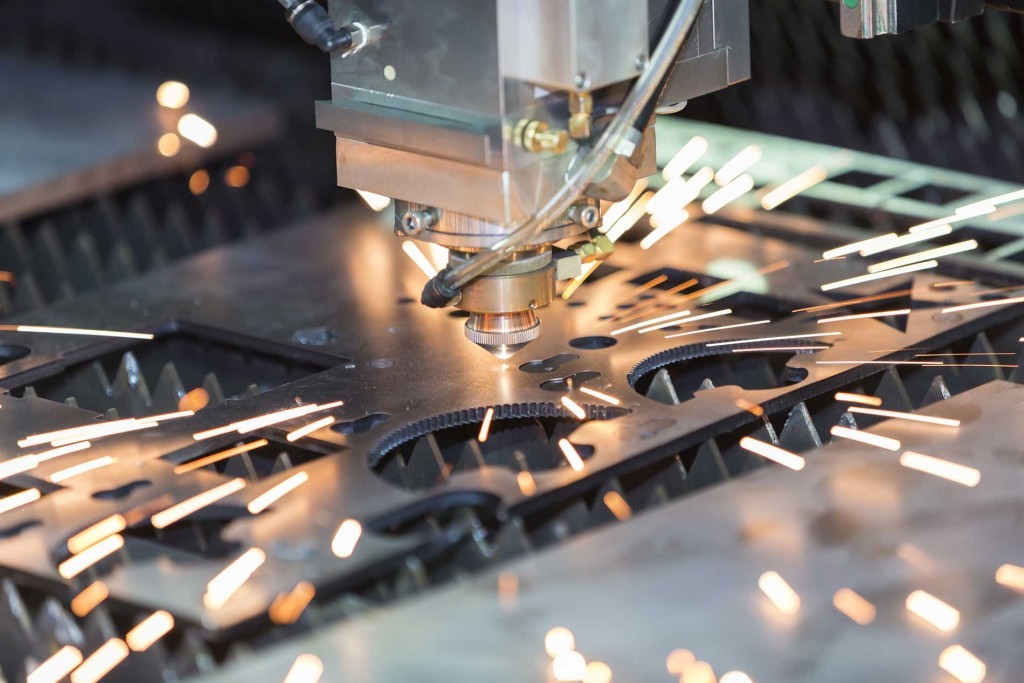

1. Laser Cutting: A Benchmark for Precision

Laser cutting is famous for its ability to produce high-accuracy and quality cuts. This process involves melting or vaporizing material with a highly concentrated laser beam, which produces smooth finishes and minimal waste. It is particularly suited to thin to medium-thick materials, including stainless steel and aluminum.

Advantages of Laser Cutting:

- Accuracy: This is particularly important in sheet metal cutting services when intricate designs require tight tolerances to be achieved.

- Rapid and Efficiency: It works quickly on the material, reducing manufacturing time.

- Versatility: It operates efficiently with all metals, like stainless steel and aluminum.

This approach often occurs in electronics, HVAC systems, and architecture, where the requirements for exactitude and accuracy are the criteria.

2. Plasma Cutting: Cost-Effective for Thick Materials

Plasma cutting is a very useful technique for cutting conductive metals, especially with medium- and thick materials. This process has various stages that are done quickly and economically by high-temperature plasma arc.

Advantages of Plasma Cutting

- Economical: It is cost-effective in heavy-duty applications for metal-cutting services.

- Consistent: It delivers consistent results for structural and automotive components.

- Efficient: It cuts the thicker material faster than other types of cutting methods.

This method is widely used in the construction and automotive industries. Its speed and cost-effectiveness make it suitable for mass production.

3. Waterjet Cutting: Precision Without Heat

Waterjet cutting is a type of cold cutting that uses high-pressure water and abrasives to cut through materials. This process does not involve heat transfer; therefore, it does not alter the strength of the material. It is most important in temperature-sensitive or delicate materials.

Why Choose Waterjet Cutting?

- No Heat Damage: Maintains the material’s original properties through cutting with no heat-affected zone.

- Versatility: Cut almost all materials like metal, composite, ceramic, and glass.

- Reduced Waste: Reduce the material waste during cutting, thus making it an environmentally friendly method.

This technique can be used for prototypes, food-grade equipment manufacturing, and other small to medium-sized projects wherein the qualities of the material need to be preserved.

Selecting The Best Option

Selecting the best cutting method for sheet metal cutting services depends on key factors:

- Material Type: Laser cutting is most effective for thin to medium-thickness materials. Plasma cutting is most effective with thicker metals. Non-metal or temperature-sensitive material can be processed with a water jet.

- Budget: Waterjet cutting is a costly process due to its uniqueness, but plasma cutting is relatively cheap.

- Precision Needs: Waterjet and laser techniques give the accuracy required for complex shapes and close tolerances.

The best alternative is selected for every project based on assessing these variables.

Precision Sheet Metal Cutting Solutions in New York City

Weldflow Metal Products offers advanced sheet metal cutting services, including waterjet, plasma, and laser cutting, in NYC. The numerous demands of sectors that rely on precise and prompt supply of their requirements are meant to be met by these services. To find out how Weldflow Metal Products’ metal-cutting service may help the company, contact us today.

Also read:

Six Ideal Metals for Superior Results in Laser Cutting Services

The Advantages of Laser Cutting for Sheet Metal Products in the Electrical Industry